- Throttle Lag

- Delayed response

- Car feeling heavy or not nimble

- Difficulty climbing hills at low/moderate throttle

- Uncertainty when passing other cars or unpredictable response at low/moderate throttle

- Stumble when shifting on manual transmissions

You name it, this has been my issue w/ my Corvette 7 since test driving at the dealership. I've tried a Throttle controller, AFM disabler, ECM Tuning, and arguably the three most talked about ported throttle bodies (PTB) out there. I have also combined some of the above w/ some success but still not enough. One just needs to hop into almost any other comparable car to feel they respond better.

After spending so much time/money, I decided to take it upon myself to find out, I also have all the equipment needed at work (measuring, testing, simulating, machining etc.)

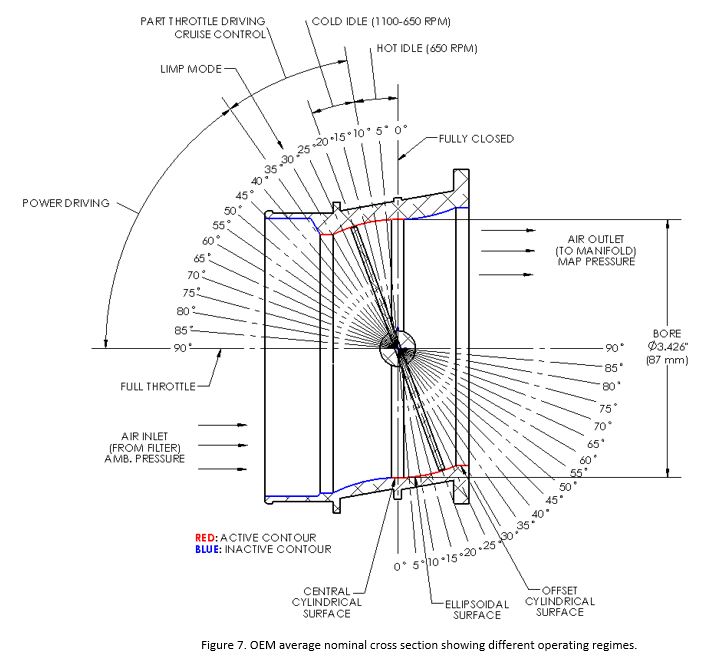

Long story short; it is the throttle body. Between idle (~5 degree throttle) to ~30 deg throttle angle the amount of mass air flow (which is proportional to power) puts our cars at a weigh to power ratio similar to that of trucks and SUV’s, both in terms of absolute value and rate of change. Not to be confused w/ the weight to power ratio that is usually published, which is calculated at WOT, above 35 deg throttle angle our engines shine. It is on the part throttle range (idle to 30 deg) that the issue exists.

I’m not going to speculate on the reasons, but I can tell you that our throttle body p/n 12678223 or 12620263 is used in many GM vehicles and that such throttle response helps w/ fuel economy. That helps to keep parts cost low and meet EPA requirements for the fleet. However, I do not think one size fits all and that a high performance car needs to sacrifice performance for economy.

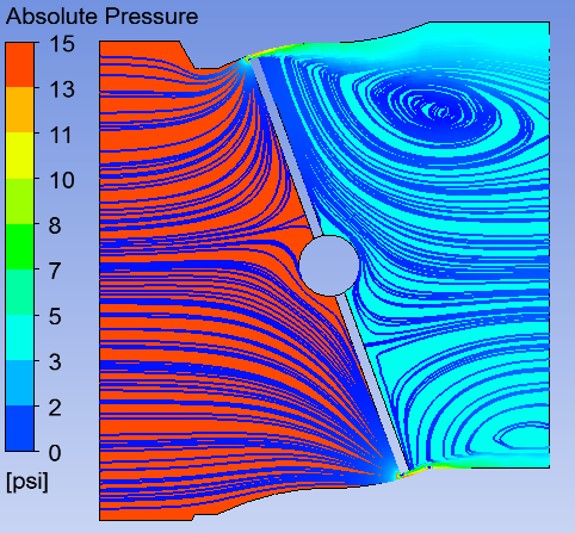

The throttle controller and the tune improve response by making the throttle plate move faster between the 5-30 deg range. Faster, but it still needs to go through a tortuous path for the air flow, and the manifold pressure doesn’t recover as fast. It is a transient process, and it is from the intake manifold where the pistons suck the air from. Notice that this is not true throttle response, it is just tricking the ECM into thinking you have pushed the accelerator pedal harder. The actual throttle response is the same, only physical changes to the throttle can make for a true throttle response.

The existing aftermarket ported throttle bodies also helped, they do change the throttle physically, but their effect only starts to take place at about 25 deg in what I thought was the best one of them. Definitely a step in the right direction, but I noticed they were not optimized and that more could be extracted from them, that is a throttle body that can increase the absolute value and rate of change of mass air flow right from idle and up to 35 degrees to achieve the same weight to power ratio (in that range) of similar high performance cars that feel nimble and fun to drive at part throttle.

Another long story short, I reversed engineered 10ea OEM throttle bodies, 3ea aftermarket ported throttle bodies, and a benchmark (competing car maker model) OEM throttle body. Optimized/modified the OEM throttle body to meet the benchmark throttle response as well as the goal stated above.

Our modified throttle bodies (MTB) are made (CNC machined) from a brand new OEM throttle body, flow and engine tested. Our design has been fully vetted by Corvette 7, Camaro 6, CTS-V owners, fully and openly tested by Corvette Forum members mainly. Driven in different conditions/modes for a few thousands of miles now at extreme temperatures and altitudes.

See pics below for more insight into what I’m talking about…and most importantly what do you think? All comments welcome.

Please visit us at : SolerEngineering.com

원본글입니다.

기존 친환경적인 스로틀에서 나타나는 단점들.. 스로틀 지연같은...것을 해결하기위해 포팅을 해서 테스트해봤는데

결과는 요렇다네요. 해외 반응도 나쁘지 않은듯?

|

김도영(SunShine) | 조회수 :5064 | 2019-07-10 (14:25)

김도영(SunShine) | 조회수 :5064 | 2019-07-10 (14:25) 이강혁(케서린아빠) | 2019-07-10 14:36

이강혁(케서린아빠) | 2019-07-10 14:36 김보겸(개미리더) | 2019-07-10 18:09

김보겸(개미리더) | 2019-07-10 18:09 김지원(Dimitri) | 2019-07-11 09:07

김지원(Dimitri) | 2019-07-11 09:07